Our strength - is our diversity

Our production creates timber building systems that tell a story and last for generations

We apply precision and passion to our craft. Every step of our production is carried out with care. We manufacture and know what is important. LENO® cross laminated timber, LENO®-ADD, wood-concrete composite system, rib and box elements, timber mullion and transom façade elements, timber frame construction or solutions with wood-based materials - we manufacture all systems and combine them sensibly.

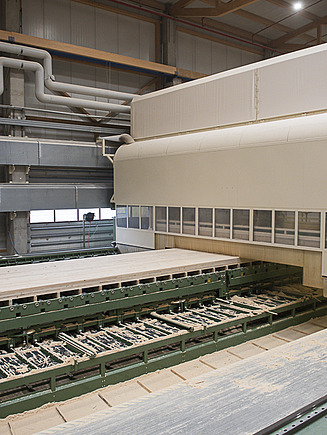

Production facility

-

Our site

Eight halls with a production area of approx. 22,000 m² are located on around 54,000 m² of company premises.

All halls are equipped with energy-saving LED lighting, are fully heated and also have an air humidification system. Among other things, this creates a pleasant working environment for our employees.

Our new five-storey office building T3 meets the Efficiency House Standard 40. Around 500 m² per floor offer plenty of space to work and feel comfortable. -

Energy supply

Untreated waste wood from our production is processed in our combined heat and power plant. This process supplies the heating energy required for the office building, the halls and the timber drying plant.

To ensure the sustainable operation of our T3 office building, the temperature in the building is regulated throughout by cooling/heating ceiling sails from renewable energy sources: T3 is cooled using evaporative cooling from an adiabatic cooling tower; heating is provided by local heating from the wood chip plant in our own production facility. The electricity requirement is partly covered by a photovoltaic system on the otherwise green flat roof. -

Craft

Our industrial colleagues, whether machine operators, fitters or production employees, have learned their trade from the ground up and understand what they are doing. Thanks to continuous training, our colleagues are always up to date with the latest technology.

We attach great importance to the further training of our people, as well as to training in the trade. -

Machinery

- Hundegger K2-Industry joinery machine

- Panel processing system (PBA)

- Robots

- CNC machining centers

- and much more

Our machines are equipped with the latest software and are controlled directly from CAD with joinery data.

High-quality production here. Manual, machine and serial

-

© ZÜBLIN Timber

© ZÜBLIN Timber -

© ZÜBLIN Timber

© ZÜBLIN Timber -

© ZÜBLIN Timber

© ZÜBLIN Timber -

© ZÜBLIN Timber

© ZÜBLIN Timber -

© ZÜBLIN Timber

© ZÜBLIN Timber -

© ZÜBLIN Timber

© ZÜBLIN Timber -

© ZÜBLIN Timber

© ZÜBLIN Timber

From material selection to implementation: sustainability at every step

We take time and money to make conscious material decisions!

Material procurement plays a crucial role in today's economy, especially when it comes to a sustainable and resource-conserving approach. We focus on:

- Regional raw materials

- Wood from sustainable sources

In line with the motto "waste nothing - reuse", we make conscious decisions to control our production processes.

Long-standing relationships with our suppliers guarantee the best quality of our raw materials. In addition, we strive to keep the distances of the material as short as possible by using regional suppliers.

We connect people, knowledge and machines

- Automation of our production lines

- Direct machine control via office interface

- Implementation of cloud computing solutions

- Use of big data and analytics