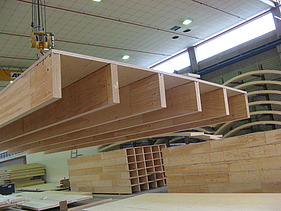

Rib elements and box elements

Spans of up to 20 m without load-bearing partition walls, widely spanned ceilings without supports or wide roof overhangs can be safely realized with our products. The load-bearing structures of rib elements consist of ribs positioned at a distance from each other, which are connected as load-bearing chords via an upper planking of laminated veneer lumber or cross laminated timber (CLT/LENO®).

If a smooth soffit is required, if elements have to be designed with insulation or with a corresponding fire protection requirement, then box elements are the right choice.

VARIANTS AT A GLANCE

Ribbed elements

They consist of spaced ribs, which are connected by an upper planking of panel materials as a static load-bearing chord.

Box elements

The use of panel materials as the bottom and top chord increases the fire resistance and load-bearing capacity of box elements.

Composite elements

Ready-to-install LENO® cross laminated timber cover panel prepared for on-site bonding with common HBV variants.

Your advantages with ribbed and box elements:

- Solution for medium to long spans of up to 20 m

- When designed as box elements, fulfillment of fire protection requirements

- Maximum dimensional stability thanks to the materials used

- Laying capacity of up to 1,000 m2 per day thanks to large-format elements

- Immediate accessibility of the elements increases construction site safety

- No drying and waiting times for rapid construction progress

Our service to you:

- Extensive reference objects

- Planning support and pre-dimensioning by experienced specialists

- High flexibility due to requirement-specific and individual use of different building products such as glulam, CLT, LVL, concrete, etc.

- Optimum material efficiency as ribs or box element

- High flexibility thanks to individual element dimensions up to b = 3 m and l = 20 m (depending on the material selected)

- Customizable and visually appealing soffits thanks to available visible surfaces

- Ready-to-assemble elements with lifting device

Ribbed and box elements in use

Your contact for rib and box elements